New Jersey recycling plant supplied glass for temporary I-95 fix

Fill material for the I-95 emergency fix was made with recycled glass from Burlington County.

Plant manager Ryan Gregor holds handfuls of crushed glass at the Burlington County recycling facility in Westampton. All of the crushed glass produced here goes to Aero Aggregates, which uses it to create glass foam like that used to patch up a fire-damaged portion of I-95 in Philadelphia. (Emma Lee/WHYY)

Much has been said about the fill material propping up the temporary lanes built after the I-95 collapse. Particularly, how the material, which looks like a wall of pumice stone, is made of processed, recycled glass.

To be clear, no one is driving over broken glass jars or beverage bottles.

Eddystone, Pa.-based AeroAggregates sourced the refill substance from a New Jersey plant.

For the past four years, Burlington County has provided more than 7,000 tons of glass to AeroAggregates to make their foam glass material.

“We wouldn’t have this type of recycled material available if our residents didn’t take the time to sort [it] out and recycle,” said Burlington County Deputy Commissioner Director Tom Pullion. Overall, he adds, more than 84 million pounds of recyclable material — cardboard, glass, and plastic — has been kept out of landfills.

Pullion said the county and AeroAggregates have had a working relationship for the past several years.

“It’s been going quite well to the point that we manufacture approximately 10% of their total [amount of materials] for the year,” Pullion said.

The county collects recycling from all 40 of its municipalities.

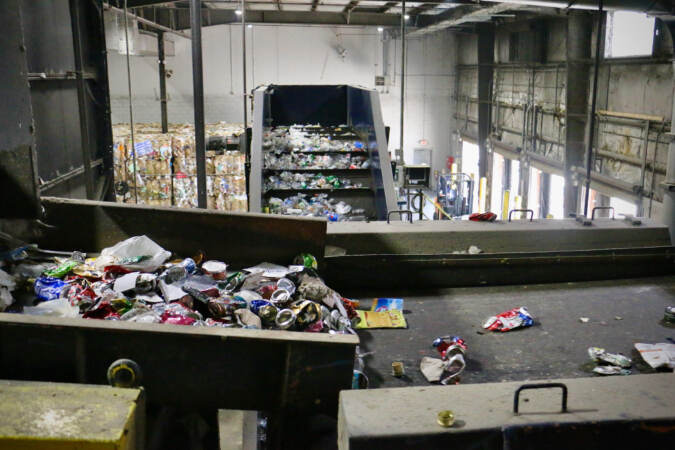

Whatever is picked up is brought back to the county’s recycling plant for processing. As the recyclables are moved along a conveyor belt, workers remove the materials that can’t be recycled, like shoes and certain other plastics such as motor oil bottles.

Plant manager Ryan Gregor explains that the first stream separates the glass and fiber. The glass falls below into a machine that breaks it.

“[A] conveyor will take [the broken glass] into what we call the crush room,” he said. “It’ll hit a crusher. It’ll crush it down to size; about three-eighths. Then into this trommel, where it’ll sift out anything larger than three-eighths.”

The glass pellets are then delivered to a stall in the back of the recycling plant, ready to be packed and shipped to AeroAggregates in Delaware County. The company pays for the shipping costs.

In addition to base material, glass from Burlington County has been used to make reusable shopping bags. Pullion said recycling can be beneficial if people are earnest in their efforts.

“I think if you’re truly working toward a benefit, you take the time to research and search out those areas where it can be used,” he said.

Get daily updates from WHYY News!

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.