Silverliner V update

The final 11 Silverliner V carshells arrived from South Korea last month, according to a monthly SEPTA report.

With that delivery, 75 carshells were being assembled in the South Philadelphia Weccacoe plant by the end of January, while 38 were being stored at the Philadelphia Port for lack of work space.

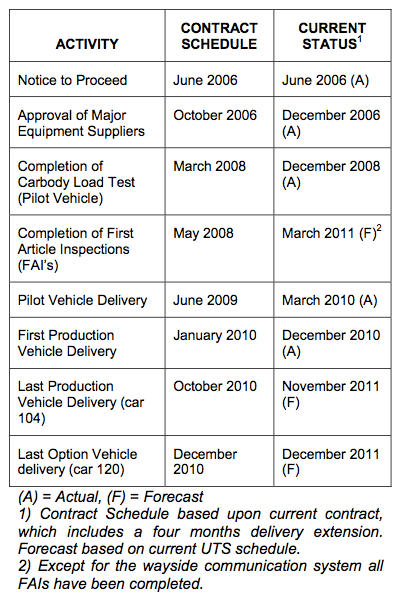

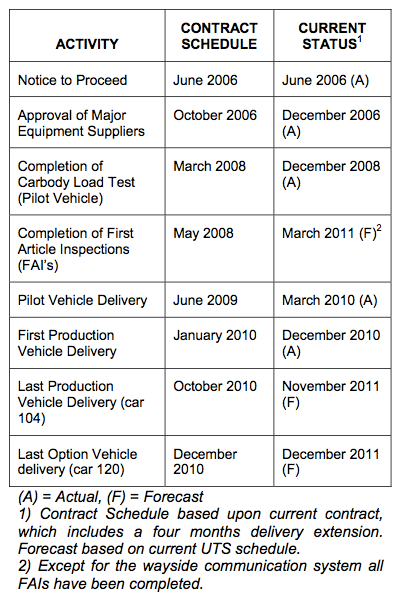

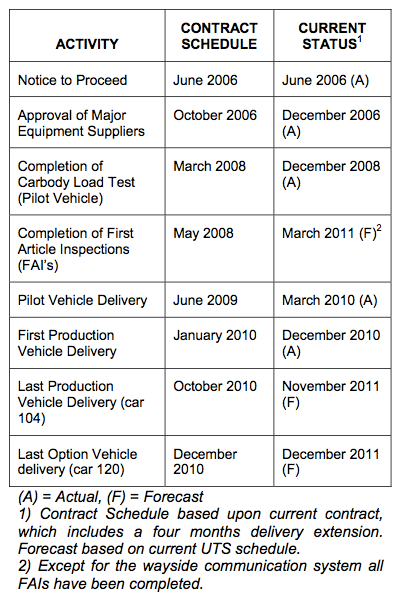

Three more completed cars were set to be delivered to SEPTA early this month, and final delivery of the 120 cars is scheduled for December ― a full year after the originally announced timeline.

(According to SEPTA’s contract with United Transit Systems, the consortium building the cars, the company owes SEPTA $200 per day for every car that’s late. SEPTA officials have said that it’s too early to begin talking about how large these damages will be.)

UTS took steps in January to address quality control issues at the assembly plant.

According to the report, additional support is being given to personnel working on passenger door installations, electrical locker inspections and water testing activities.

The company also began to reorganize assembly line work to improve material flow and coordination at the end of January, with the hope of resolving persistent production issues.

SEPTA is also shipping one of three pilot cars up to a testing plant in Canada to verify that changes to the car’s heating system have resolved reported problems. Testing is scheduled to go through March, and if successful, changes will be made to the cars’ design.

Contact the reporter at acampisi@planphilly.com

The final 11 Silverliner V carshells arrived from South Korea last month, according to a monthly SEPTA report.

With that delivery, 75 carshells were being assembled in the South Philadelphia Weccacoe plant by the end of January, while 38 were being stored at the Philadelphia Port for lack of work space.

Three more completed cars were set to be delivered to SEPTA early this month, and final delivery of the 120 cars is scheduled for December ― a full year after the originally announced timeline.

(According to SEPTA’s contract with United Transit Systems, the consortium building the cars, the company owes SEPTA $200 per day for every car that’s late. SEPTA officials have said that it’s too early to begin talking about how large these damages will be.)

UTS took steps in January to address quality control issues at the assembly plant.

According to the report, additional support is being given to personnel working on passenger door installations, electrical locker inspections and water testing activities.

The company also began to reorganize assembly line work to improve material flow and coordination at the end of January, with the hope of resolving persistent production issues.

SEPTA is also shipping one of three pilot cars up to a testing plant in Canada to verify that changes to the car’s heating system have resolved reported problems. Testing is scheduled to go through March, and if successful, changes will be made to the cars’ design.

Contact the reporter at acampisi@planphilly.com

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.