The state of Pennsylvania’s bridges, Part 3: Inspecting and managing them more efficiently

ListenAgencies tasked with bridge maintenance rely on visual inspections to assess safety. Some say new technology can help them better manage bridges.

This is the third story of our three-part series on the state’s bridges.

About seven years ago, the Bridge Maintenance Engineer for the South Carolina Department of Transportation, Lee Floyd, was concerned about one of his bridge’s ability to hold up while a replacement was built. He placed sensors on the bridge to monitor how it behaved and found that actually he could keep it open without any temporary repairs.

“If we had not sensored we probably would’ve gone ahead and spent the money to repair the bridge,” Floyd said. “But by using the sensors it gave a sense of assurance and safety and we were able to avoid that extra expenditure.”

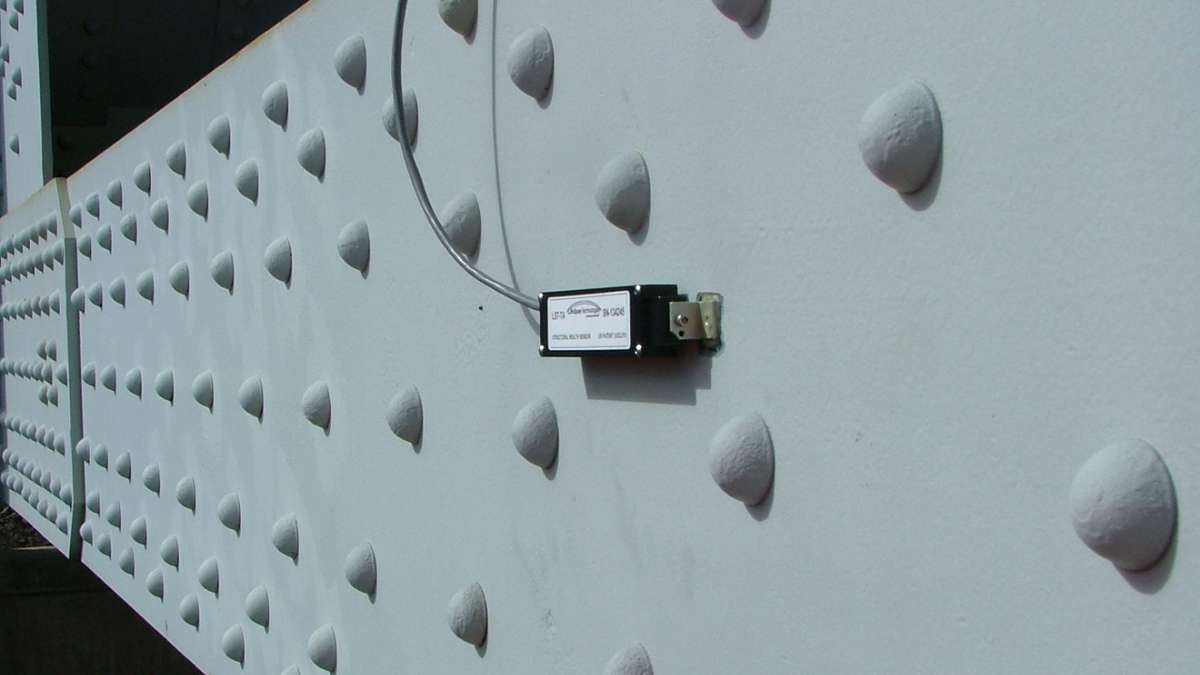

He estimated he saved $700,000 in unnecessary repairs on that bridge. Since then, Floyd has embraced these sensors, which produce detailed information on how a bridge is moving and reacting to everything from traffic to wind. He now uses them on other bridges as a kind of structural health monitoring tool, to make management decisions about the state’s bridges.

“The amount of money we’ve spent so far on structural health monitoring is probably no more than I would say $275,000 and we have more, more than recovered that cost,” Floyd said.

About 12 percent of South Carolina’s bridges are structurally deficient. In Pennsylvania, 23 percent of bridges are structurally deficient, making it the state with the biggest bridge problem in the nation. Many Pennsylvania bridges are old, expensive to maintain, and resources are perpetually thin. Agencies tasked with maintaining the bridges in the state rely on traditional, visual inspections to assess safety, but people like Floyd say the new technology can help them better plan and manage their bridge assets. So far, Pennsylvania is not using the sensors for structural health monitoring.

Pennsylvania has used sensors, but not much

Pennsylvania has dabbled with sensors. Pennsylvania’s Department of Transportation, or PennDOT, has used sensors since the 1980s, but in a narrower way, mostly to check that repairs on bridges are working properly. Since 2000, 25 bridges have been instrumented for this purpose.

The Turnpike Commission installed sensors on one of its bridges to see what it could learn. The Commission had already authorized contractors to fix one problem, but the sensors found those repairs were not necessary yet, and instead revealed a whole other issue the Commission had to address. Still, the Commission went ahead as planned. Jim Stump, with the Commission, said the agency learned a lot from the sensors, but ultimately had to resolve the problem bridge inspectors identified during visual inspections.

“Was it actually needed? Probably not, yet it will give it a better condition rating of the bridge because inspectors will not see that section loss,” Stump said.

Visual bridge inspections

Visual bridge inspections were established in the 1970s, following the collapse of a bridge over the Ohio River that killed 46 people. They’re primarily focused on assuring safety. “It’s not really a management system,” Floyd said.

During the biennial inspection of the Fort Pitt Bridge in Pittsburgh, Steve Haluska walked along the bridge deck with a clipboard in hand. Haluska works for SAI Consulting Engineers, Inc., a company contracted by PennDOT to inspect the bridge. Before climbing in the bucket truck to examine the floor beams of the upper level, he checked on the deck’s expansion joints. The joints allow the bridge to move and breathe as materials contract and expand. He used a folding wooden ruler – “nothing too high tech, just need to get the measurement,” he said – to measure the joints and then compared the measurements to the last time they were checked, in the summer.

“It has contracted so the bridge is moving like it should,” he said, and moved on.

It was, he said, “at least” his twelfth time on the bridge, a complicated structure requiring many trips to complete one inspection. Inspectors check bridges for rust, cracks, peeling paint, missing bolts and document everything. It’s a low-tech way to analyze a bridge, and it’s a process designed to be conservative so that human error does not result in tragic bridge failures. Industry stakeholders – from engineers to Department of Transportation managers to the people actually selling these sensors – agree that visual inspections are necessary. But the new technology could supplement them, reducing how long they take and in some cases their frequency, while increasing both safety and efficiency in management.

How do the sensors work?

“Conservative is better than not conservative. But it may be putting undue restrictions on a bridge if it is way too conservative,” said Andrew Herrmann, a former president of the American Society of Civil Engineers. He said for complicated bridges especially the new technology can be a useful tool.

“You can actually see a truck drive over a bridge and see how it affects the structure, how much load, how much stress and strain it’s actually putting on the individual members. So there’s a range that you want to be in and it’s a safe range,” Herrmann said.

If the sensor detects a problem, an alarm goes off on the bridge manager’s computer or phone.

The gathered data can be used to create very detailed models of the bridge, which show how it acts under static and dynamic conditions, something not really done with current bridge modeling. And if calibrated properly, the models can show where inspectors should focus their efforts and how repairs will affect the bridge.

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.