How one shipbuilder impacted Philadelphia and the world

Local historians Torben Jenk and Kenneth Milano say the Cramp Machine Shop, then Turret Shop, was part of a business whose impact on Kensington, Fishtown and the city as whole was enormous.

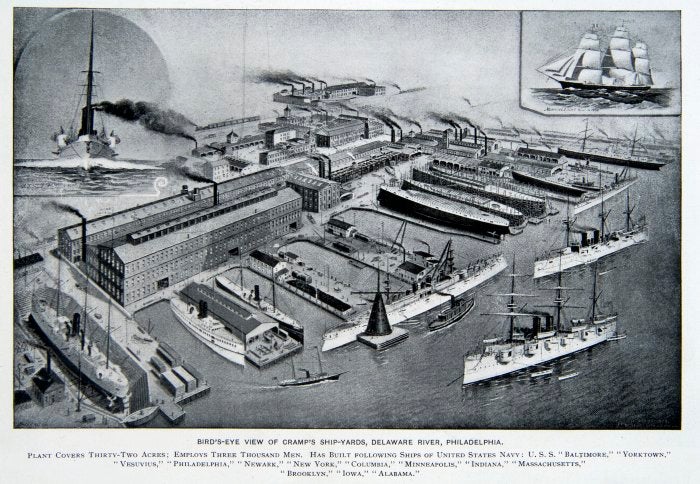

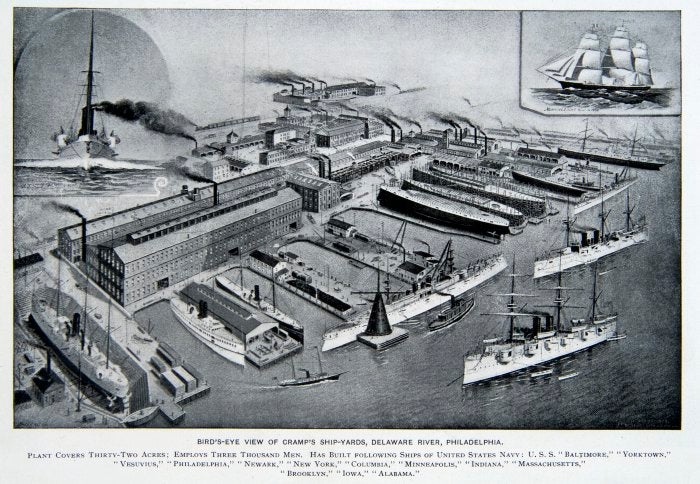

William Cramp & Sons, as the original business was called when it opened in the 1830s, and the war reborn Cramp Shipbuilding Company, not only employed generations of families, but brought fame to the neighborhood. “You can find on eBay on any given day postcards from back in the day, because it was a tourist attraction,” Milano said.

William Cramp’s family had built its wealth through the fishing industry, Milano said. The first ships Cramp made were wooden.

The Cramp company was “the only American ship company that successfully transitioned from making wood hull ships to steel hull ships,” Jenk said.

Although William Cramp became extraordinarily wealthy, he stayed in the neighborhood. “He lived in a small, two-and-half story house on Palmer Street until 5 or 6 years before his death in 1879,” Milano said, but not so his sons who moved to the “new money” neighborhoods around North Broad Street.

In the early 1900s, Jenk said, William Cramp & Sons made submarines and tugboats.

The company became more famous when it built Teddy Roosevelt’s Great White Fleet, Jenk said. “Roosevelt was trying to project American power,” Jenk said. Most ships meant for battle are painted gray, so they disappear into the water, but not these. “He had them painted white so you couldn’t miss them. He sent them all around the world to show that America was a superpower. And a lot of them were made by Cramp.”

Note that the flagship of the Great White Fleet is moored downriver a few miles from the Cramp site.

In that era, the shipyard employed about 10,000 people, Jenk said. It also created demand for many supportive industries, such as glass manufacturing, which also sprung up in the neighborhood, Milano said.

Read previous PlanPhilly Cramp Shipyard coverage and check out Jeffrey Totaro’s evocative interior photos in the slideshow.

Martin B. Abbot, the architectural historian who researched the machine shop building for PennDOT, said that Cramp subsidiary I.P. Morris Co., which engaged in the manufacture of steam engines, established a department to design hydraulic turbines in 1904, and in 1913, the machine shop was built specifically to make these turbines for hydroelectric dams.

Abbot took photos and video of a steel beam that still bears a mark of its destiny from the building’s construction. Cramp No. 6, it says.

Jenk, who is friends with former owner Joel Assouline, used to give historic tours of the building. He was also taken with that beam. “When you assemble a building with a steel frame, you use a crayon to mark the beams,” he explained. “We are there 100 years later, and you can still see that, because everything else around it rusted, but the crayon protected that part.”

The full height of the building is divided into several levels. These are open to the main floor, balcony-style, and parts could be moved to different areas with the use of heavy-duty cranes that are still in place. The largest could move 70 tons.

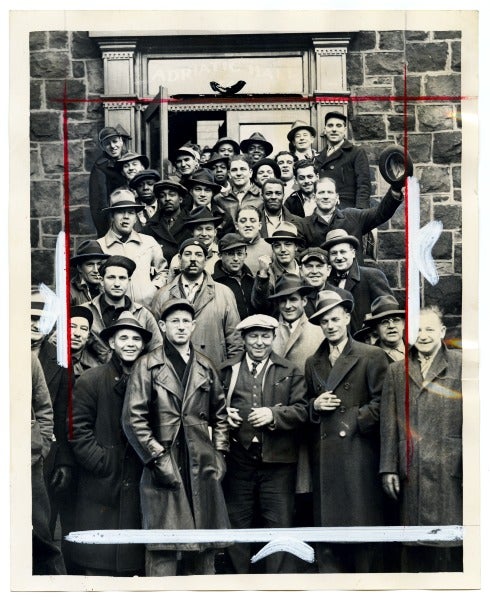

Cramp did a lot of government contract work during World War I, and government contracts required companies to allow unions if the workers wanted them. Cramp was unionized, and workers frequently went on strike to make the company meet their demands, Jenk said. Cramp “caved in and gave the workers what they wanted,” he said. “They were making so much money from government contracts that they really didn’t care.”

But finances tightened considerably when the war contracts ended, Jenk said. When the government contracts went away, he said, so did the union requirement. In January of 1921, it was announced that Cramp was an open shop, Jenk said. The union walked out and management fired them and brought in replacement workers.

“Women set up auxiliaries, and they got all the grocers, doctors, pharmacists, butchers and milk dealers not to sell to the scabs,” Jenk said. “The government had to intervene.”

In August 1921, Cramp started laying off the replacement workers, Jenk said, and the business shuttered in 1927.

Abbot said the next World War led to the company’s reopening, under another name – the Cramp Shipbuilding Company. That’s when the machine shop became the Turret Shop where naval gun turrets were manufactured, he said.

It was during World War II that the Cramp complex employed the most people, about 18,000, Jenk said. One old image Jenk provided shows the Cramp building, as large as it is, was just one of many huge structures that are already gone.

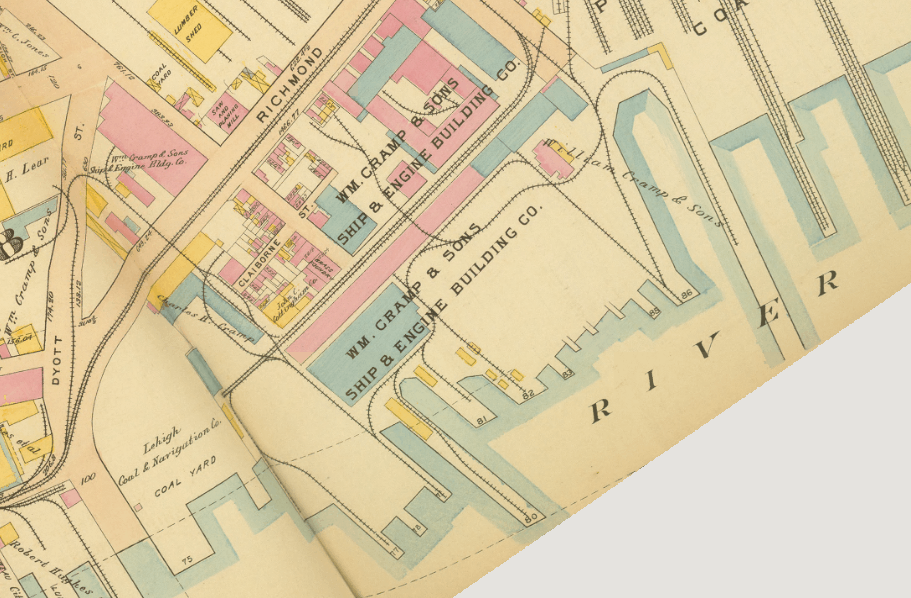

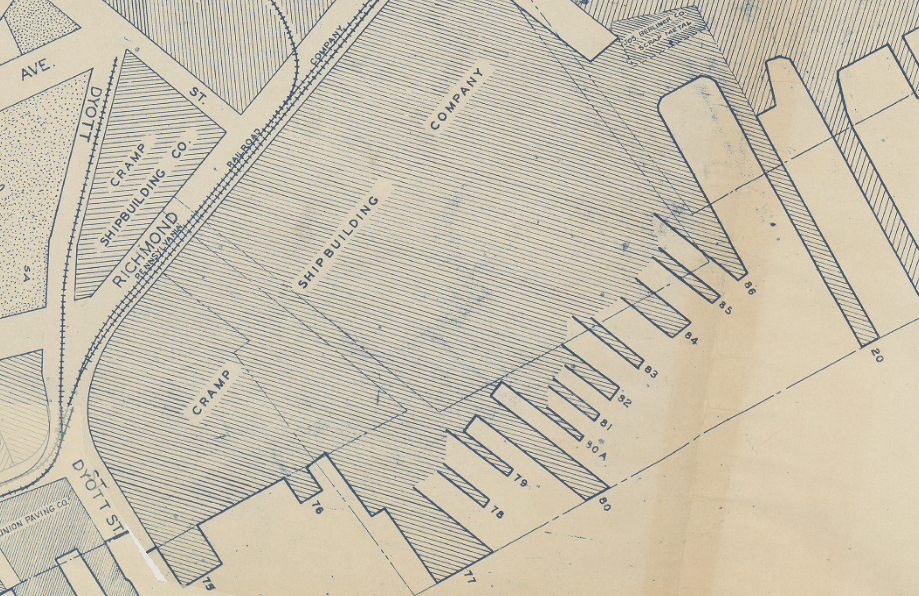

“There was a railroad in the building, and whatever was made, they could open huge doors and wheel it out, across Richmond Street to the docks,” Jenk said. “There was a whole series of docks where they could assemble the parts of the ships.”

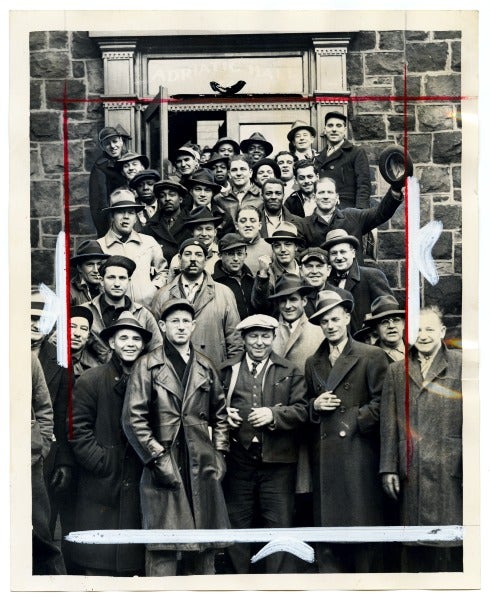

What stands out from other images is the integrated war-time workforce: African Americans and women had a huge role in shipbuilding.

Just as the end of World War I led to the shuttering of William Cramp & Sons, the end of World War II led to the end of Cramp Shipbuilding.

From 1945 until recent years, the building was used as a warehouse.

When the building is gone, the site will be criss-crossed with the ramps of the I-95 Girard Avenue interchange.

Contact the reporter at kgates@planphilly.com

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.