Climate Fixers: Less than 1% of clothing gets recycled. This University of Delaware researcher has a plan to fix that

Fast fashion is creating more and more clothing waste. A PhD student at University of Delaware has a new and simple solution.

This story is part of the WHYY News Climate Desk, bringing you news and solutions for our changing region.

From the Poconos to the Jersey Shore to the mouth of the Delaware Bay, what do you want to know about climate change? What would you like us to cover? Get in touch.

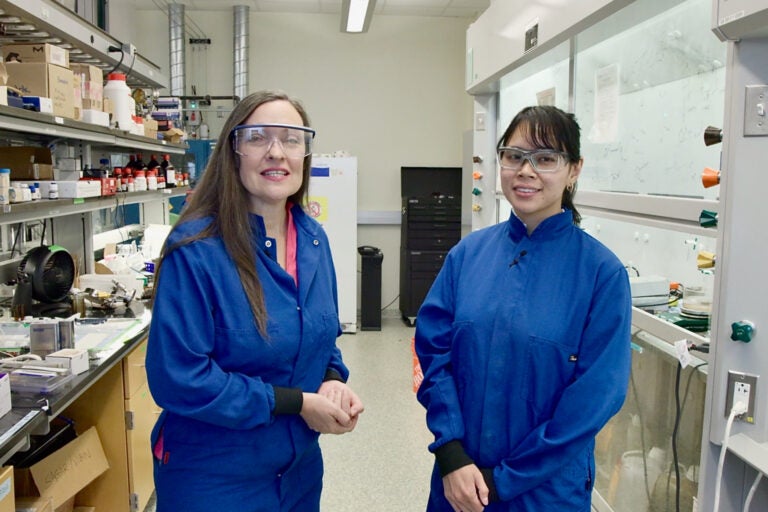

At a chemistry lab at the University of Delaware in Newark, chemical engineering PhD candidate Erha Andini is carefully snipping off pieces of my shirt and shoving the slivers into a test tube.

The problem with my shirt, like a lot of clothing these days, is that the fabric is made from several different materials, which come from fossil fuels and are mixed in with cotton. That makes it almost impossible to recycle through a mechanical process.

“Right now, recycling clothes is very challenging because modern garments consist of different types of fibers all interlaced together, and that makes separating them into their pure components to be very challenging,” Andini said.

So, as part of her doctoral work, Andini set out to solve this problem, and her results were recently published in Science Advances.

Less than 1% of clothing worldwide gets recycled. Combined with the rapid machinery of fast fashion, where the global demand for fiber is expected to jump to 149 million tons by 2030, that waste stream will likely grow exponentially. Andini said 90 million tons of textiles are tossed in landfills each year. Textiles are also a significant source of microplastic pollution.

Fossil fuels are the building blocks for synthetic fibers, so demand for those clothes and disposal, especially the burning of textile waste, contributes to global carbon emissions.

“I wanted to solve this problem mainly after learning that so little of our old clothes are recycled back into clothes,” said Andini, who grew up in Indonesia before coming to the U.S. to study. “And I thought that’s very interesting because when you go to stores like H&M, for example, you’ll see on the tags, [it says] made from recycled polyester. But in reality, that’s not the polyester that exists in clothes. It came from plastic bottles.”

More than 50% of global fiber production in 2021 was polyethylene terephthalate or PET — the same material used to make plastic bottles, according to her paper.

Andini also learned through her research how much shorter the lifespan of modern clothes is compared to previous decades.

“So that’s quite sad, and that’s a loss of valuable resources that in theory we could have diverted back to clothes.”

Andini said her solution is simple. She adds ethylene glycol, a commonly used organic compound, to bits of my shirt, along with zinc oxide as a catalyst. The tube is then microwaved for 15 minutes. The process breaks the shirt down into its component parts, which she says, if scaled-up, could mean taking those building block textiles and turning them back into clothing.

Andini’s advisor, Dion Vlachos, is optimistic about taking the process into the real world.

He said the microwave they use in the lab is no different than the one you have at home. “It’s modular, it’s portable, it’s very rapid, and you can use green electricity from the grid to do it,” Vlachos said.

Andini said her research has also changed her buying habits. She no longer buys clothing unless she knows she’s going to wear it “at least five times,” Andini said. “I think before I buy.”

Get daily updates from WHYY News!

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.