Temple University engineers tap into the powers of soy to heal wounds

Researchers are seeking FDA approval for their soy-based bandages, which they say are an alternative to other synthetic and animal-derived products.

Listen 3:57

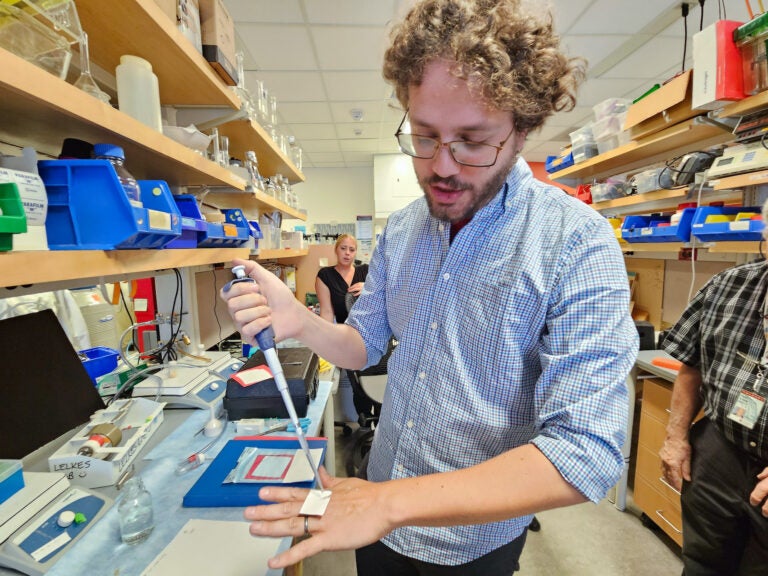

Temple bioengineer Jonathan Arye Gerstenhaber applies liquid to a small piece of OmegaSkin, which is made from soy, for the bandage material to adhere to the skin. (Nicole Leonard/WHYY)

From Philly and the Pa. suburbs to South Jersey and Delaware, what would you like WHYY News to cover? Let us know!

At a laboratory benchtop surrounded by bins of funnels and syringes, robotic parts, beakers, microscopes and other machines, Temple University bioengineer Jonathan Arye Gerstenhaber pulled out a thin square piece of white material.

Not much larger than a postage stamp, it felt smooth and weightless.

“Right now, it looks like a solid white fabric,” Gerstenhaber said, but it’s not really fabric at all in the traditional sense. “Actually, this is soy protein. It’s so white because it’s mostly air.”

Gerstenhaber placed the material on the back of his hand and, using a pipette, added drops of a liquid solution to the white square, which quickly became see-through as it soaked into his skin to form a gel-like layer.

“Now if you touch it, it’s stretchy,” he said. “Now, it feels like skin.”

This material, made of isolated and concentrated proteins from the soybean plant, was invented by Philadelphia engineers to create a natural bandage product that can be cheaply made and better help skin heal from wounds and burns that typically cause scarring.

After more than 10 years of research and experimentation, the scientists are now seeking approval from the U.S. Food and Drug Administration to manufacture the product on a large scale and start targeted human clinical trials.

“A scar is not going to be made of the right cells that make up a healthy skin,” Gerstenhaber said. “Our goal is to teach your body to heal itself, recover the natural healing process that somehow stalled due to this injury.”

Skin is the human body’s largest organ, and healthy skin contains sweat glands, hair follicles, collagen and other components that contribute to hydration, elasticity, temperature regulation, sensation and more.

These components can become severely damaged or even lost with serious wounds or burns.

Peter I. Lelkes, who is the Laura H. Carnell professor and founding chair of the Department of Bioengineering at Temple University, said wounds that heal with scarring are often missing those components that make up healthy and functional skin.

“There is a difference between just healing and regeneration,” Lelkes said, “where we entice the body to contribute to the healing process, to regenerate the skin to do these things again.”

But why use soybean as the basis for a new bandage?

Lelkes said he got the idea while traveling in China. At dinner one night, he was served dishes made with yuba, also called tofu skin. The food staple is made from soybean protein and comes in thin sheets that can be used in soups or to wrap, fill and fry vegetables and meat.

“When I saw this membrane [material], wound healing came to my mind,” Lelkes said.

During their research studies and clinical trials in pigs and rats, researchers and engineers found that their soy-based bandage material and product can improve skin cell regeneration even more than other products made from synthetic or animal-derived materials.

In human clinical trials, Gerstenhaber hopes to answer questions about how thick the bandages need to be and how often new bandages need to be applied to achieve successful healing and cell regeneration.

At least one of these clinical sites is planned for Temple University’s School of Podiatric Medicine to test the soy bandages on patients who suffer from diabetic foot ulcers, which can be chronic and hard to heal.

While these soy-based bandages likely won’t replace the typical household Band-Aid or Neosporin for minor cuts and injuries, Gerstenhaber hopes they can be incorporated into existing wound care strategies and even one day replace therapies like skin grafting, which involves taking healthy skin from one part of the body to replace burned skin.

The scientists and engineers have partnered with Pittsburgh-based startup NeuEsse to manufacture the bandage product and conduct additional testing trials. CEO and founder Joseph Connell said he became interested because of his own experience as a burn victim and survivor.

“I was never supposed to walk again,” Connell said of severe burn injuries he got on his leg at 10 years old, which required extensive skin grafting procedures.

“Anyone who knows a severe burn victim will tell you it doesn’t heal. It has grown, stretched, faded for the last 58 years of my life, and it’s still a hideous scar,” he said. “If something were available not only to prevent you from taking skin from a healthy part of your body, but to help heal with minimal to no scarring, it would be a blessing for the people involved.”

Temple engineers said they hope to use their soy bandages in human clinical trials, and with help from NeuEsse, make it commercially available by next year.

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.