Delaware farms embrace freezer technology for its poultry waste

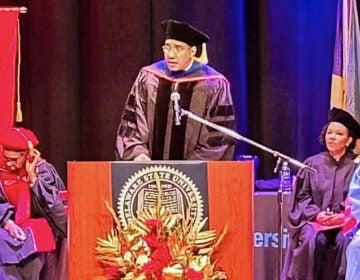

On farm freezer units (Zoe Read/WHYY)

Delaware farmers could find their traditional composting of poultry waste giving way to a new on-farm freezer technology.

The freezer units store dead birds, which can then be recycled into products like bio-fuel. In turn, farms save money and time, and prevent diseases like avian influenza.

Fox Chase Farm in Milsboro, which houses about 150,000 chickens, is one of several farms reaping the benefits from the technology.

“I think this is the way the industry will go,” said Terry Baker, owner of the farm and co-founder of Greener Solutions, an agriculture equipment company.

Greener Solutions bought four units several years ago to test out the technology on Baker’s farm. The company found numerous benefits for the environment, and found the product to be cost effective.

“We do not need the nutrients being generated from composting, and by recycling material we can preserve the industry, and the equipment has a side benefit of being bio secure, where birds are away from scavengers, and it can’t spread disease,” Baker said.

Poultry growers in other parts of the U.S. have been using on-farm freezer collection units for routine mortality for more than 20 years.

The National Resources Conservation Service recently announced that freezer collection units are now eligible for cost-share funding in Delaware and Virginia.

The Delaware Department of Agriculture allocated a total of $50,000 for pilot programs at Delaware farms, and plans to fund the installation of the technology in the future.

Poultry is a huge economy builder for the state of Delaware. Last year alone, the state produced more than 240 million broiler chickens.

U.S. Sen. Tom Carper, D-Delaware, said the new technology, which costs about $4,800 a unit, is an example of how the State can improve the economy and the environment mutually.

“We have a huge investment we made over the years in the agriculture industry,” he said. “We’ve made all these investments, created a lot of jobs, a lot of peoples’ incomes depend on a vibrant poultry industry, so we do everything we can to preserve that industry.”

Benefits economy and environment

Several chickens die every year due to heat exhaustion, according to Greener Solutions. Almost 23,000 tons of dead poultry was generated on the Delmarva Peninsula in 2013, for example.

In more recent years, deceased birds have been used for composting, which helped the ground receive more nutrients. However, to this day the ground has too many nutrients, according to Greener Solutions, which can lead to polluted air and waterways.

Composting also is time consuming and labor intensive, and requires the use of costly equipment, such as tractors.

The new technology is cost effective for farmers because it requires less labor, and because waste can be recycled. Greener Solutions estimates that an average farm with about 67,000 birds will save about $1,600 a year in operational costs.

The alternative technology also can help reduce the risk of avian flu, which recently has impacted dozens of farms throughout the Midwest.

Previously, poultry waste was stored in composting sheds, which would attract predators and flies, potentially spreading the disease to other areas.

“The industry has multiple procedures and technologies, and not any one of those tools is going to be the silver bullet to protect us for all time,” said Victor Clark, co-founder and president of Greener Solutions.

“It’s about making sure we have a nice mixture and menu of options so we can tie down lose ends on all corners of the farm, and that’s what we hope to do with these is add an additional tool of protection.”

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.