How NASA repairs its rovers on Mars, without ever touching them

NASA's rovers are labs on wheels, doing work on Mars, while being directed by scientists and engineers here on earth. How do they repair rovers from millions of miles away?

Listen 8:30

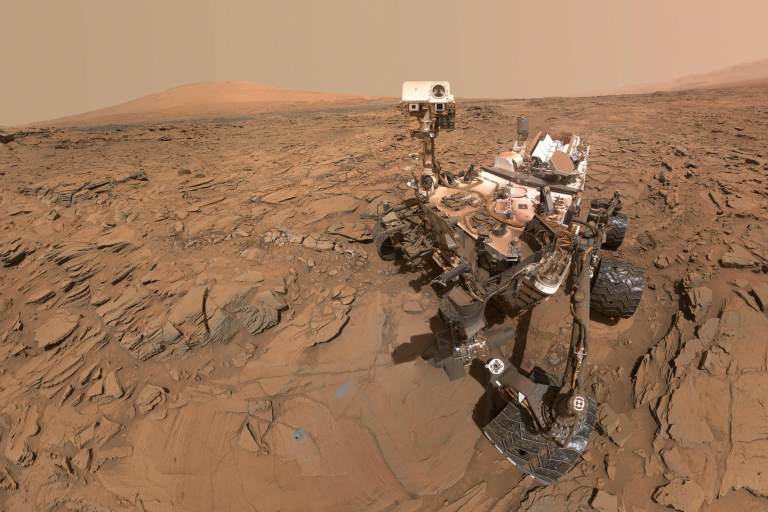

A self portrait of Curiosity from 2016. (NASA/JPL-Caltech/MSSS)

This story is from The Pulse, a weekly health and science podcast.

Subscribe on Apple Podcasts, Spotify or wherever you get your podcasts.

NASA’s Curiosity Rover landed on Mars in 2012, and people around the world cheered. Humans have yet to land on Mars, and the rover lets scientists run experiments, such as testing soil and rock samples for evidence of liquid water, or chemicals that could point to signs of life.

But what happens when the $2 billion lab on wheels runs into problems? How do engineers on Earth fix the rover from millions of miles away?

In 2016, Curiosity’s drill, the key instrument to collecting those rock samples, stopped working.

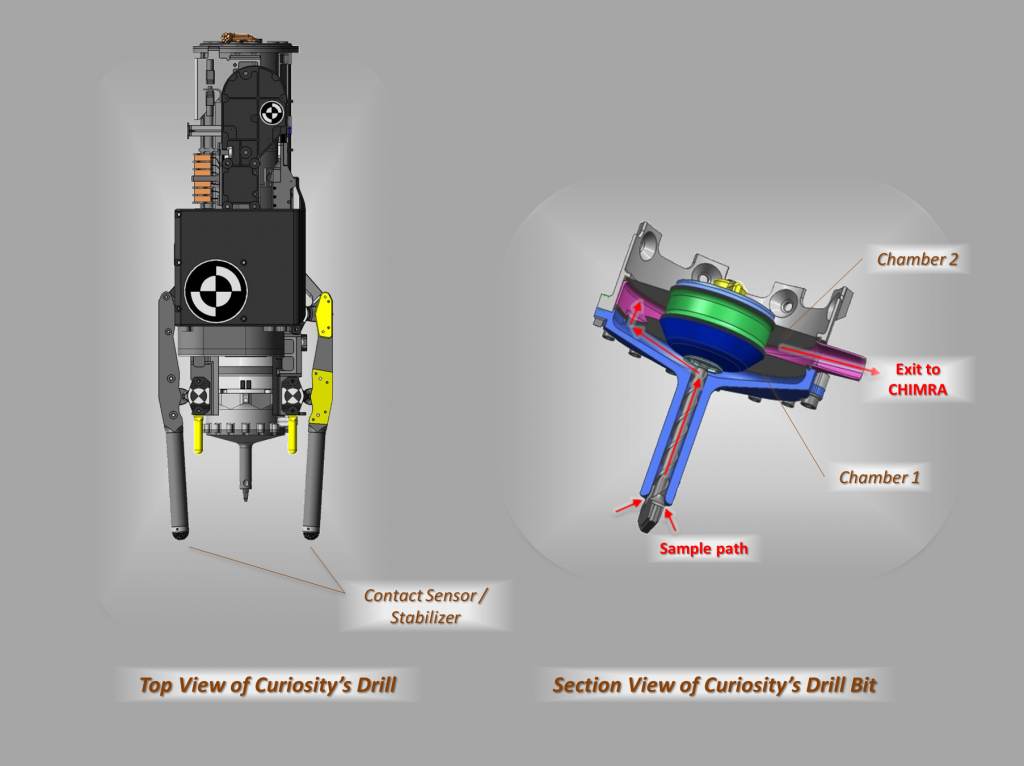

This is how the drill works: A drill bit makes holes that are a little smaller than a dime, and two prongs hold the rock or whatever it is Curiosity is drilling into, to keep it steady.

Imagine trying to drill a hole into a block of wood on Earth, said Megan Lin, mechanical engineer and deputy project manager. First, you would hold the wood, or clamp it to a table, to keep it steady. Curiosity’s two prongs are like the hands or clamp stabilizing the thing being drilled.

“Now, you’ve created a nice stable workspace, it’s almost like a drill press,” Lin said.

Because of this design, Curiosity also needs a feed mechanism to poke the drill bit out. There were some occasional problems with the feed mechanism getting stuck. Lin and her colleagues spent months testing different solutions, which meant months without any drilling or soil samples.

Finally, they managed to get the drill to poke out again, but it still doesn’t go in and out smoothly, the way it’s supposed to.

And the engineers decided that if the drill is going to be stuck in one position, it would be better to have it stuck poking out, rather than stuck inside. The engineers tested the drill, and it still works.

But there are two more problems:

First, Curiosity no longer has the two hands to hold whatever it’s drilling steady. Now, it’s like holding a drill with one hand, which means it can dangle and move around. But at least the drill is working again.

Second, engineers had to come up with a new way of getting the rock samples out of the drill.

Subscribe to The Pulse

The original design had a funnel and a sieve, called the CHIMRA system, to send the rock samples into the science instruments for testing. But that relied on the drill being able to move in and out

Emily Lakdawalla, who wrote a book about the design and engineering of Curiosity, explained it like this: “The drill feed is now extended all the way out all the time, that funnel isn’t lined up with CHIMRA anymore, and so the whole CHIMRA system is useless. It doesn’t get used anymore: You can’t portion out material; you can’t sieve it; you can’t deliver a fine portion, or a coarse portion, or any of those things.”

The engineers did a lot of testing, and they landed on a solution: They could make the drill spin backwards, to shake the samples out of the drill and into the science instruments.

“It’s not as accurate as it used to be,” Lakdawalla said. “They’ll get big chunks in with the small chunks, they can’t ever truly know if they have delivered what they hope they do, they can’t ever know beforehand how much material is actually stored inside the drill chamber. So there’s a lot more uncertainty with this solution, but it is still enabling the rover to use its science instruments and continue its science mission. It’s better than nothing.”

It took the engineers more than a year to come up with that answer, but that’s what repairs to Curiosity look like, said Megan Lin.

“Because we can’t touch the hardware on Mars, a lot of what’s available to us in terms of fixing it is in software or in the procedures that we ourselves follow, so you’ll see a lot of fixes to very mechanical problems are to use that instrument differently.”

That means less a repair and more like: How can the engineers and scientists work around the problem to still do the science they want to do, in a different way?

The teams at NASA have two things going for them: Hardware that’s more powerful than it needs to be, and their own creativity.

The powerful hardware creates some slack for engineers to draw on. For example, Curiosity has two computer systems when it could get by with just one, which has proved useful, said Lin.

“Anytime you want to upload new flight software to your rover, you kind of want to have that capability of having two computers, because otherwise it’s akin to doing brain surgery on yourself while you’re still awake,” she said. “It’s really nice for a computer when you can … put it to sleep and do a full shutdown and upload your new flight software and test it out without that being your main brain that’s operating.”

The engineers also rely on their creativity to think how they can use the existing equipment and the Martian environment to their advantage.

A good example is a maneuver to fix the wheels that the engineers have come up with and tested, but have not had to use yet.

Curiosity is a lab on wheels, specifically six aluminum wheels, about 20 inches in diameter. Those wheels get worn out eventually. Imagine rolling six aluminum cans back and forth over sand and rocks — eventually, the can is going to roll over something sharp enough at just the right angle to cut a hole.

Also, the design is such that the part of the wheels that face inside the rover is under a little more stress than the part of the wheels that face outside. So if any part of the wheels break, it’ll be the inside. Which means as Curiosity is rolling these cans back and forth, a wheel break could mean that a can opener has cut open the top part, so the edge is no longer smooth, but jagged. And the jagged edge is on the side that’s facing the cables, the instruments … the valuable bits you do not want to damage, said system engineer Evan Graser.

“The risk of cutting a cable is one that is of great concern: Not only would that basically mean that you would lose a wheel, you would not be able to drive that wheel anymore, and we’d have to drag it along with us, but you could potentially cause electrical damage even further up the chain with the actual motor controller.”

So Graser and his colleagues tested a way to intentionally drive a damaged wheel into a rock to rip and break off a jagged edge.

“It was one of the coolest things I’d ever seen. I was very excited that part of my job was to go break something on purpose,” he said.

They tested it, and it works. The wheels are nowhere near that level of damage now, but if that scenario plays out, NASA now has a plan for it.

That’s a lot of work to put into fixing one drill or one potential wheel problem, but right now, these rovers are all we have on the surface of Mars, said Emily Lakdawalla.

“The rovers are like an extension of ourselves,” she said. “It’s almost like another set of senses or another, an extension of your body … into a place that humans can’t ordinarily go.”

Curiosity was expected to last on Mars for two years. But thanks to the redundant designs, and the engineers on Earth working on problems, it’s been there for almost a decade.

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.