3-D printing poised to change manufacturing, and the curriculum

ListenNot long ago, if you were a mechanical engineering student, that meant hours and hours in the machine shop, perfecting your lathing and milling. But with the rise of 3-D printers — machines that can build objects based on a computer design — that is beginning to change.

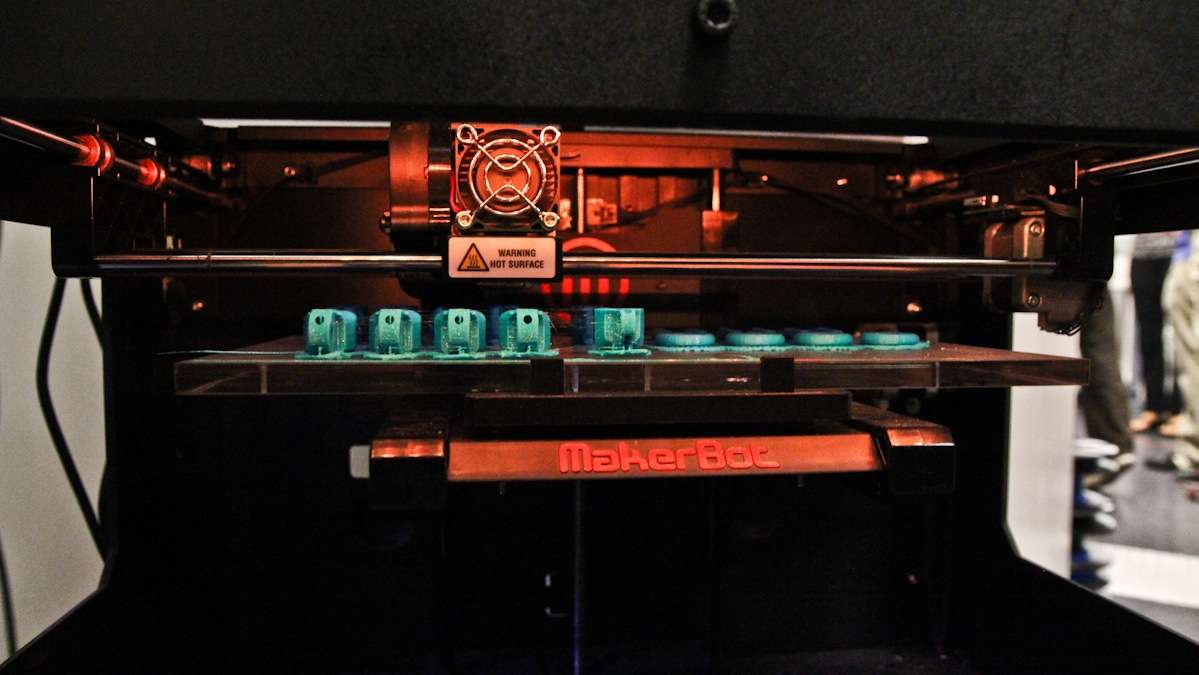

To make sure the next generation is well versed in the technology, the mechanical engineering department at the University of Pennsylvania is building up its 3-D printing facility. Chair of the department, Robert Carpick, said they now have six new entry-level MakerBots to complement other, more advanced machines.

Fundamentally, 3-D printing is different from traditional manufacturing, which is based on the idea of removal — a bit like sculpting from stone.

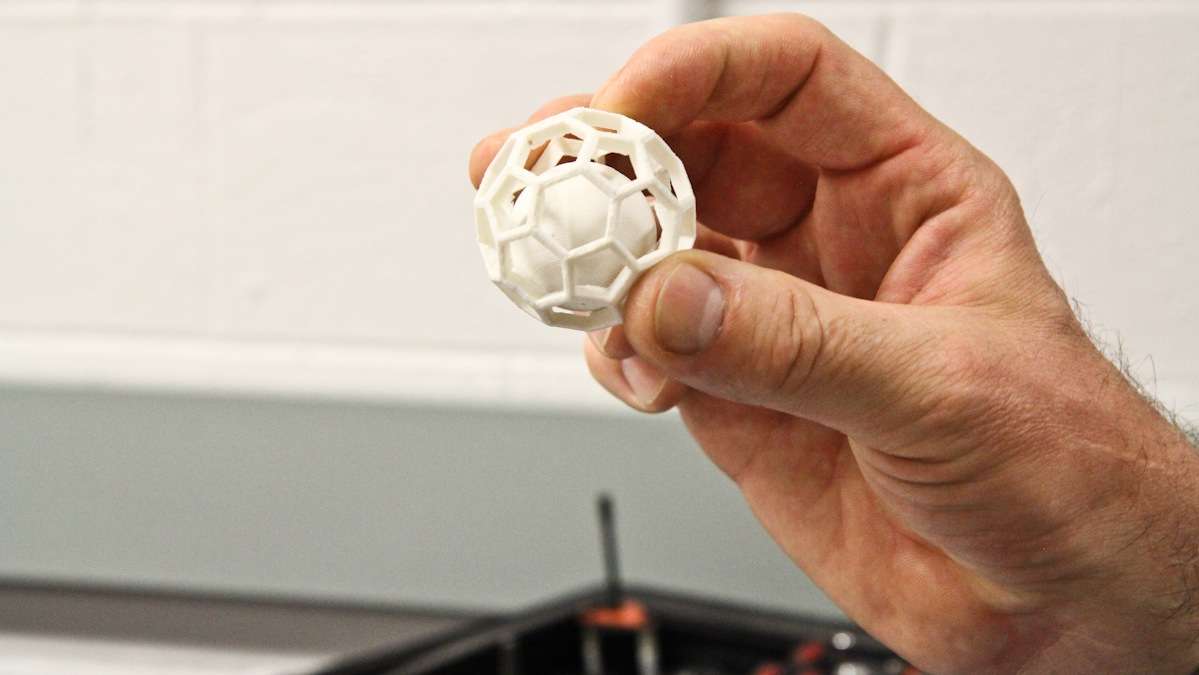

“Here, it’s just the opposite,” said manufacturing manager Peter Szczesniak. “You’re building from nothing, layering up, creating separation between design features, between components in order to achieve an end result.”

Making stuff this way means you can easily create objects with interlocking parts. Szczesniak said that was either impossible before, or much more difficult and expensive.

Now, he said, “The sky is the limit. If you can imagine it, you can make it.”

Nicholas Parrotta, director of the teaching labs, said another benefit for students is being able to move quickly from design to prototype.

“Instead of what would have taken probably an entire day to machine something while you’re developing a project,” he said, “you could go through four, five, six rounds of iteration to really nail down the exact geometry and functionality that you need.”

That perk has already aided the seniors studying under Katherine Kuchenbecker, an associate professor in the department. Several years ago, she said, students ran through six or seven designs to perfect a fingertip monitoring device that can detect whether a patient is going into shock.

As 3-D printers become cheaper and easier to use, another advantage is that they will begin to redefine what it means to “make” something, expanding the opportunity beyond engineers.

“Machine tools require some safety training; sending a file to a 3-D printer doesn’t,” said Carpick. “I think you’re going to see people who ordinarily wouldn’t have gotten involved in making and designing things who now can.”

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.