Teach Me: Where science meets booze

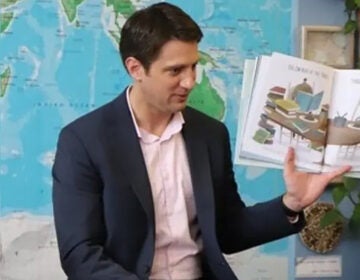

"Modern alchemist" Ron Gomes poses in front of the history-making bourbon. (Avi Wolfman-Arent, NewsWorks/WHYY)

Two months ago, Painted Stave Distilling in Smyrna made Delaware history when it released the first ever legally made bourbon in the history of the First State.

It was a landmark moment for one of Delaware’s first craft distilleries. But no time to rest. Just one week earlier, in mid-November, Painted Stave got to work on a new batch of their history-making spirit.

Painted Stave co-owners Ron Gomes and Mike Rasmussen invited us to take a peek at how the distilling process begins. Along the way, they explained their approach to the liquor-making process.

Fire up the mill

When it comes to making alcohol, ground zero is in fact the grinding process.

The day begins when Rasmussen flips on the Painted Stave’s trusty mill and begins griding 275 pounds of rye. As it’s reduced to a fine, flour-like substance, the rye travels through a shoot and into a vat filled with 350 gallons of water. The corn goes through the same process, after which the resulting frothy mixture is heated and turned into a polenta-like mash.

Enter the centrifuge

After about a week of fermentation, the process starts to get nerdy.

Rasmussen takes a sample of the fermented mash and runs it through a centrifuge. This separates the sediment from what’s called the “beer,” a liquid substance that tastes similar to–you guessed it–beer. You may know this liquid by its Scottish name, “the wart.”

Rasmussen then injects the “beer” into a density reader. He wants to make sure the density has dropped to a specific level, which tells him the sugars were eaten by the yeast and the fermentation process was successful.

Still the one

Finally, the substance heads to the still, where it is heated again and the alcohol is harvested. After separating out the undesirable byproducts of this process–known as the “heads” and the “tails”–Rasmussen feeds the alcohol into barrels where it will age for two years.

Painted Stave stores its bourbon in the same cavernous room where it grinds, ferments, stills, and bottles its liquor. It’s a one-room factory of sorts. Gomes and Rasmussen purposefully keep doors open to the outside, which means changes in weather over the next two years will undoubtedly alter the character of the bourbon as it ages.

Painted Stave embraces that uncertainty. It gives each vintage a distinct character and reveals insights about how little changes in the process can make a difference in the final product. That’s one of the traits that distinguishes craft distillers from their corporate brethren, who tend to value consistency.

To the lab

The technical precision required in this process demands a scientific mind. Luckily, Ron Gomes is a scientist. Like, a real deal scientist.

Prior to partnering with Rasmussen, Gomes was an assistant professor of Orthopaedics at the Penn State College of Medicine. There he directed a lab where he ran a “bone metastasis research program” and did a little “cartilage engineering” on the side.

At Painted Stave Gomes’ unofficial title is “master alchemist,” and he tries to bring scientific thinking into his work as a distiller. Gomes and Rasmussen liken creating a new liquor to running an experiment. First there’s the hypothesis: Wouldn’t this combination taste good? Then the two create a prototype. If that’s successful, they scale it up until eventually they’re distilling an entire batch.

To inspire these experiments, Gomes and Rasmussen read a lot. And they’re not reading trade magazines, Gomes says, but rather the more comprehensive “literature” on the process and history of various spirits.

From all this research and testing have come some pretty wild ideas. Painted Stave makes a vodka infused with scrapple. They have a gin that tastes more like lavender than juniper. And there’s surely more to come.

For Gomes, Painted Stave is a more rewarding venue for experimentation than the lab. Back in his days as a scientist, he would spend years working on a drug or research project. In his new job he can “put a new drug on the market every ten days or so. So the reward from tinkering or trying to create [is] a little bit quicker to realize.”

And for a couple of guys whose tinkering knows no bounds, that’s a satisfying proposition.

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.