Sidelined Silverliners: Repaired Regional Rail trains should rollout this month, normal service by October, says SEPTA

“An ounce of prevention is worth a pound of cure,” Benjamin Franklin wrote two centuries ago. The phrase has become axiomatic, but not automatic, as SEPTA has painfully learned this summer when small cracks in the equalizer beams on nearly all of its relatively new Silverliner V cars hobbled Regional Rail service. When SEPTA purchased those cars just a few years ago, neither the authority nor Hyundai-Rotem, the manufacturer, performed fatigue tests on the faulty part before putting the cars into service.

Now they know better, after weeks of round-the-clock testing to determine what caused the tiny cracks in the beams, which help stabilize the railcars. Later this week, SEPTA will pick from two alternative replacement parts—each designed differently from the defective beam and from one another—and then ramp up production and installation of those new beams to get its Silverliner V cars up and running again starting later this month, said SEPTA General Manager Jeff Knueppel. But first, prototypes of those beams will undergo a week-long stress test, which, Knueppel says, will simulate the wear-and-tear of 40 years of service.

Starting the week of August 21st, around 10 cars a week will return to service. The defect sidelined all 120 of SEPTA’s Silverliner V cars, meaning it will likely take upwards of 12 weeks—or into November—before all the cars are back on the rails.

SEPTA hopes to return to a regular schedule before then, however: Services should be back back to normal by October. Relying entirely on its fleet of older Silverliner IV cars, SEPTA has been unable to run full service during rush hours.

SEPTA will also lease more cars from the MARC transportation authority in Maryland, said Kneuppel. An additional 12 cars should go into service before Labor Day, increasing the total number of leased cars to 40. SEPTA is also leasing cars from NJ Transit and Amtrak.

The transportation authority also plans to announce an express bus service to run along five Regional Rail lines in the near future, said Knueppel. While the bus service will take longer than the Regional Rail, due to traffic, the buses will be cheaper for riders, who will pay the standard bus fare.

SEPTA has made numerous adjustments to its schedule since the defects were discovered just before the July 4th weekend. SEPTA says they will make further Regional Rail schedule adjustments after Labor Day, when ridership usually increases as summer vacations end and school years begin. Trains could be even more cramped in September, warned Knueppel.

The defects have not been cheap for SEPTA. After the cracks were discovered, SEPTA offered refunds to monthly and weekly Regional Rail pass holders. That cost $235,000 for July alone. While exact figures were unavailable, Kneuppel estimated that Regional Rail ridership was down 10-20 percent compared to the same time last year. It’s unclear how many of those riders will return once regular service resumes.

On top of refunds, Knueppel said that the leased railcars have cost around $600,000 a month so far, and will increase to around $1 million when the additional MARC trains arrive sometime shortly before Labor Day. SEPTA has also incurred increased overtime costs, hired additional engineering consultants, and put extra wear-and-tear on their Silverliner IV fleet. Estimates of those expenses aren’t yet available.

Under its contract with Hyundai-Rotem, SEPTA is entitled to liquidated damages set at $200 per out-of-service railcar per day. That sums up to $720,000 a month. SEPTA’s losses outpaced that by at least $115,000 in July alone, and will likely continue throughout August. As additional cars are returned to service, they will be subtracted from the $200 per day damages amount. When asked about the potential of a lawsuit, Knueppel demurred, saying that Rotem had been cooperative, but that SEPTA would need to see what the losses would total in the end.

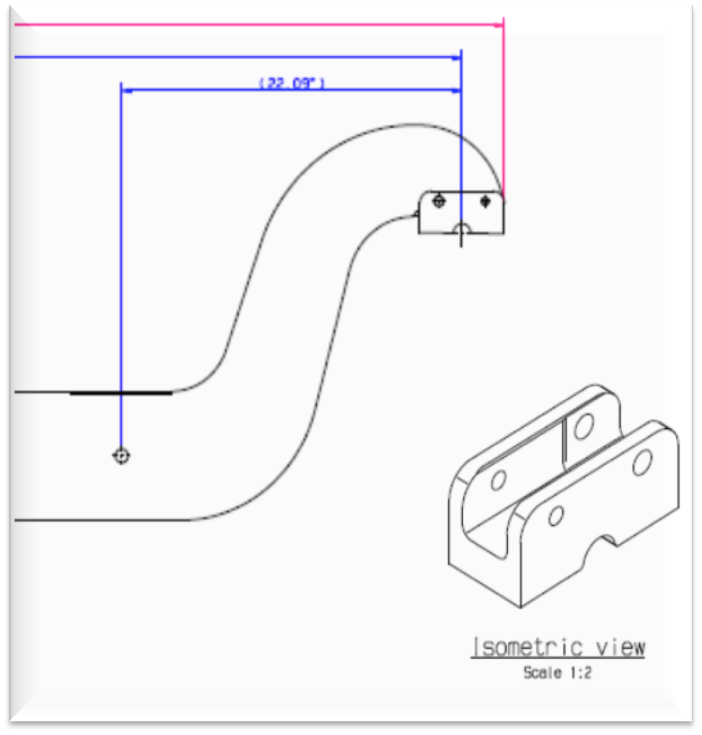

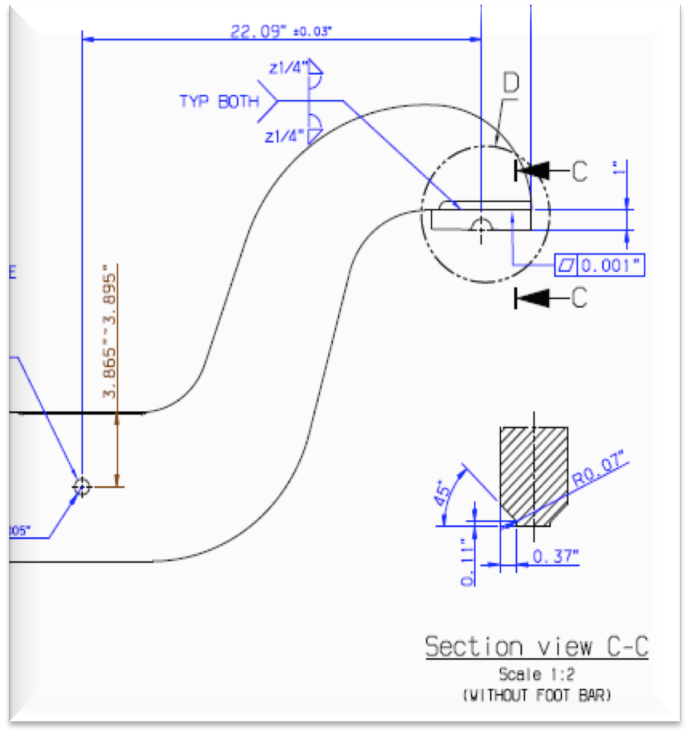

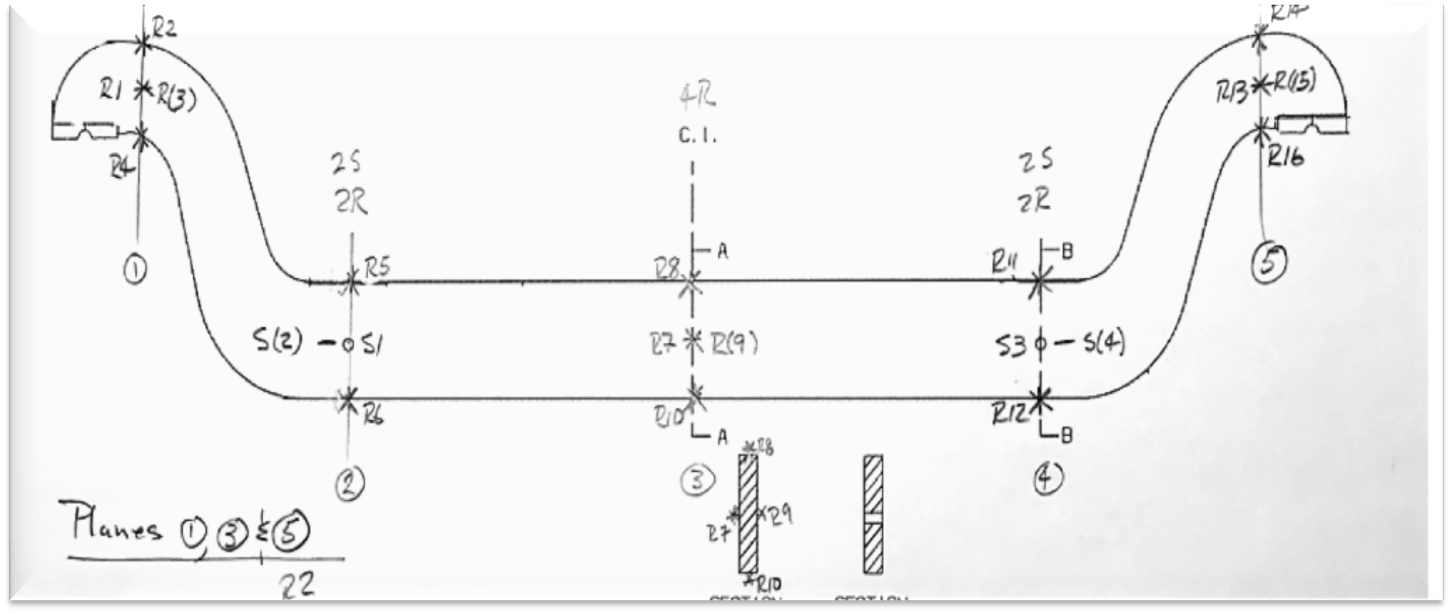

What caused the widespread defect in the equalizer beams? According to Knueppel, it was a combination of poor design and bad manufacturing. The Silverliner V’s equalizer beam, unlike those used on the Silverliner IVs, are built out of machined steel with a welded foot, rather than a single solid piece. The cracks appeared near the welds. Hyundai Rotem’s marketing and business development manager, Andy Hyer, blamed the speed on which those cracks appeared on the failure of the subcontractor, HiCorp of Zelienople, Pa., to adhere to the design specifications.

But even if the specs were followed, said Knueppel, the cracks would have eventually appeared anyway, thanks to the equalizer beam’s flawed design.

Knueppel said he was confident that the newly-designed replacement beams would last where the current crop failed, thanks to weeks of testing and computer modeling. “We have really good data,” said Knueppel. “We know exactly how those beams perform. The final test is the fatigue test.”

When the faulty part was first designed, built, and put into service, it never received a fatigue test to simulate the repeated loading, unloading and running of a railcar over the years, in the span of about a week. Neither were other parts of the railcar’s trucks, which bear the brunt of a train’s weight. Instead, Hyundai Rotem and SEPTA relied on computer projections based in part on the performance of similarly-designed equalizer beams on other types of trains.

Knueppel said that SEPTA’s engineers, as well as consultants from LTK Engineering Services, performed exhaustive inspections of the Silverliner V’s other parts and “no one brought up a concern about truck assemblies.” Knueppel said that SEPTA might consider stress testing the non-defective parts, but for now they are “performing satisfactorily.”

Hyundai Rotem’s Hyer was unable to say how much the fatigue tests cost to perform. Over two weeks, three prototypes each of two replacement options will undergo tests simulating six million rides. One design option under consideration uses a pinned foot, whereas the other uses a welded foot again with design modifications. Hyundai-Rotem will decide which design to use, and will make that decision before the fatigue tests finish. That means there is a risk that a poor result could force Hyundai Rotem to cancel production and installation of the equalizer beam it picks, and then start with the other. That would set back service recovery at least two weeks.

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.