As hyperloop design finalist, Drexel team bringing the ride stuff

ListenIn 2013, the famed inventor and billionaire Elon Musk laid out an idea, a sort of “moonshot” for transportation. Calling it the hyperloop, he envisioned it reaching speeds in excess of 700 mph, propelling passengers in a solar-powered trainlike pod from San Francisco to Los Angeles in 35 minutes.

But Musk and his team at SpaceX weren’t interested in designing and building the hyperloop themselves. Instead, they put out a call for ideas from around the globe based on their suggestions. And this week, students from Drexel University will be among 120 finalists pitching their prototype.

“The transportation industry is actually one of those industries that hasn’t been revolutionized in a long time,” says Oliver Tillman, a senior engineering major at Drexel. “And I think that is a little overdue.”

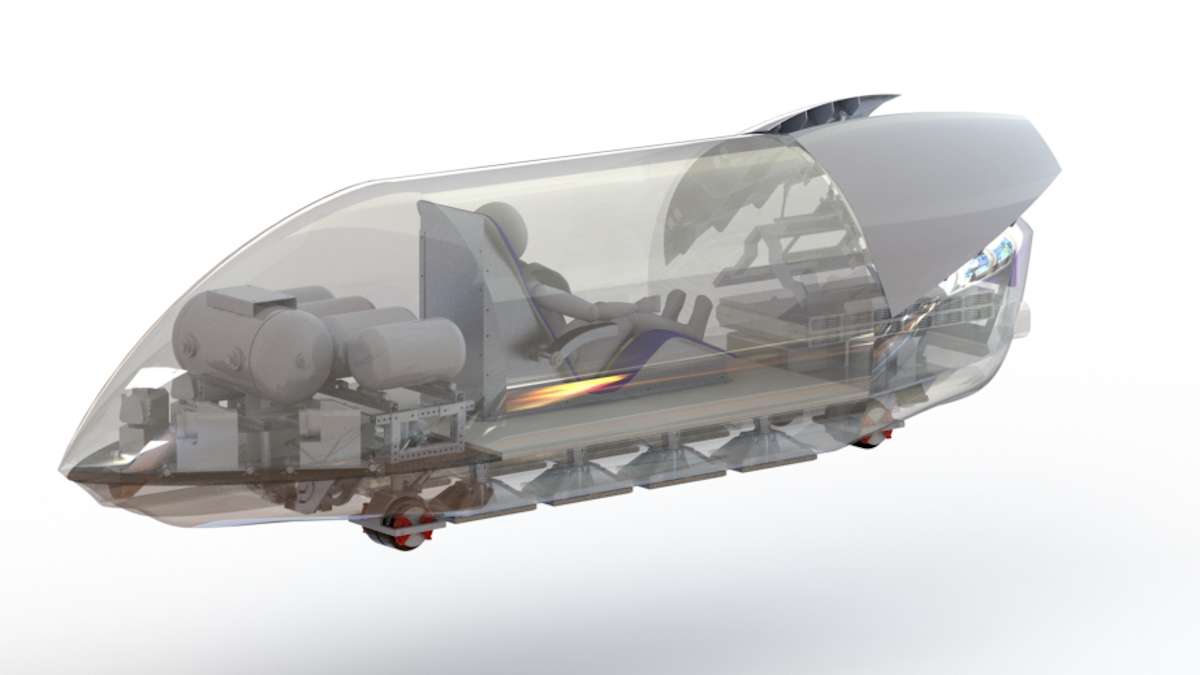

Tillman is part of a team of 80 students — not just engineers, but also product designers and computer scientists — who have spent six months or so working up a vision for the hyperloop pod, designing out every element of a prototype, including an air-suspension system.

The hyperloop reaches its impressive speed by reducing friction. That’s accomplished by designing an aerodynamic shape for the unit, as well as having it shoot through the tube without actually touching it.

Drexel’s vision starts with a layer of graphite.

“Graphite is naturally imperfect. Meaning that, on the microscopic level, there are millions and millions of little holes in which air, liquids can travel through,” says Tillman.

The idea is to install a layer of graphite bearings on the bottom of the pod, then force pressurized air through them, so the pod floats along the track.

“It is essentially riding on a layer of air, like an air hockey table. It never touches the ground,” he says. “It is just riding on this layer of air, thousandths and thousandths of an inch high, so you can’t even see it when it’s running.”

Tillman pulls out a test bearing, manufactured by Aston, Pennsylvania-based company New Way. It’s slick looking, slightly larger than an iPod, with a little valve on one side. He plugs it into an air compressor, the kind you’d find on any construction site.

“You have air coming out of this right now,” he explains. “Almost virtually silent.”

Tillman places the bearing on a foot-long length of metal that’s a stand-in for the hyperloop track.

“When I lay this down on the aluminum track, does it look like there is anything underneath there? It just looks like the graphite is sitting on top of the aluminum just like before. Now when you apply some pressure, and stiffen that column of air beneath the bearing, you’ll notice it slides along almost like it is on ice.”

It is just like an air hockey table, but picture the puck pushing air down, rather than the table forcing air up.

A full-size hyperloop pod would rely on eight massive bearings to keep it off the track’s surface, with an electric motor (Tesla is also the brainchild of Elon Musk) propelling it down the tube.

SpaceX is reportedly in the process of building a length of test track in California, and it will invite finalists chosen from this weekend’s event to test their designs this summer. The team from Drexel likes its chances.

“When you’ve seen the amount of work we’ve put in and the way we represent ourselves,” says Frederick Wachter, a junior majoring in engineering, “I think it is very clearly shown that we are going to have a very good representation there.”

WHYY is your source for fact-based, in-depth journalism and information. As a nonprofit organization, we rely on financial support from readers like you. Please give today.